Organic Oil Recovery Improves Productivity of Existing Reservoirs

by Roger Findlay

A transitional technology producing excellent results in extracting hard-to-reach oil is attracting the attention of many large operators. Ancient, resident microbes are used to liberate large oil deposits in depleted reservoirs, thanks to science uncovered by studying the humble Australian koala.

It began in almost outlandish fashion, with a scientist’s fascination with the complex digestive system of an Australian marsupial, the koala. Today, it has evolved into a green technology that is helping major producers around the world potentially reach billions of dollars of oil that they feared they could never access or bring to the surface.

As the pressure on the oil and gas industry continues to grow, to find new ways to operate with less impact on the environment, Organic Oil Recovery (OOR) is reducing the need for further exploration. Instead, it is helping producers focus on the reservoirs already in situ to extract even more precious resource—at very low cost—from deep below the ground or seas, across a myriad of jurisdictions and geographies.

The OOR team is now working with a growing list of blue-chip clients from 23 countries across the globe, to help them get that precious resource with healthy returns. In some cases, this can mean upwards of a 1,000% return on investment and millions of dollars of extra barrels of oil, to keep the world running while new means of powering the planet continue to be developed.

It is estimated that 65% of the world’s oil in existing fields is trapped in rocks and fissures, unable to be accessed when utilizing current technologies, at an economic cost of over $300/ton. This enhanced oil recovery (EOR) process is liberating that very oil.

THE SCIENCE

The small, but agile team in OOR—a partnership between the UK’s Hunting PLC and California based Titan Oil Recovery Inc.—utilizes the science that was born from that humble koala to target hard-to-reach oil droplets and release them to the surface, with no impact on the reservoir or surrounding ecology. It’s a true low-carbon solution to an age-old problem.

This new process uses totally organic and benign ingredients. It enables producers to reduce lifting costs and increase recoverable reserves in reservoirs that might be nearing the end of their economic lives, with no requirement for any additional and very costly capital expenditure.

Even when the harsh and shocking economic winds of a global downturn saw the oil price hit $30 or less, OOR has proven to increase a well’s profitability by an impressive average of 92%.

The technology is also more than capable of being used at any stage of a field’s life, to drastically reduce lifting costs and increase oil output significantly.

The technology was originally born out of Australian innovator and inventor Noel Carroll’s fascination with how koalas can digest normally harmful eucalyptus leaves and survive on the nutrition-limited diet. The eucalyptus oil found in the leaves is poisonous to most other animals.

Dr. Carroll found that the solution lay in unique microbes in the koalas’ gut that enable the marsupial to not only break down dangerous toxins in the leaves but thrive on the “cellular” food. The koala is peculiarly fussy, wanting only leaves for its diet with a mix of less than 55% water and 2% oils before it will begin to enjoy its sustenance, Fig. 1.

OIL FIELD ADAPTATIONS

After discovering the secrets behind the koalas’ diet, the scientists then began a 30-year quest— costing in excess of $20 million—to see whether the technology could be applied to oil production across the globe. OOR has now successfully adapted the principles to the vagaries of environments as diverse as the wild and cold waves of the UK’s North Sea to the hot and arid deserts of the Middle East.

The innovation’s success has generated further demand for the process. To date, the low- carbon technology has been applied to 52 oil fields, across four continents, and it has a success rate of 94%.

In simple terms, the technology means you can get more oil from hard-to-reach places with no extra capital expenditure. This can help businesses delay decommissioning assets, preventing the necessity of spending potentially hundreds of millions of dollars and instead enabling production teams to keep much-needed revenues flowing. It is also highly successful in reducing damaging and dangerous hydrogen sulphide gas, which can cause significant problems to operators of land- or sea-based wells. The H2S is the bane of the industry, and it can sour wells, reduce production and prove highly corrosive to various structures and platforms that are costly to install and maintain. OOR can reduce the production of H2S, thereby saving companies potentially billions of dollars in investment that seeks solutions to this long-standing bugbear.

The OOR process is deployed in a simple, five-step implementation process. This allows operators to manage the risk of technology deployment, with the transition from one step to another being the decision of the operator alone. As the technology does not require any significant capex spending, the costs of each step can be kept cost-effective.

OOR’s five-step process includes:

- Field screening of reservoir characteristics.

- Produced water analysis.

- Pilot test.

- Targeted water flood.

- Full-field application.

Once field screening identifies customers’ reservoirs that fall into the OOR sweet spot, specific samples are taken from designated wells and sent under controlled conditions to the lab in California for sophisticated microbial and DNA analysis. The scientists work to identify, from potentially trillions of other microbes, which type is the most useful to deploy the technology on.

The sampling is even now uncovering microbes never before seen or recorded by scientists, causing great excitement in the scientific field. It is believed that the trillions of microbes locked deep below ground may constitute as much as 9% of the planet’s total living organisms.

Once the experts identify the DNA of the key microbes in situ, a complex nutrient package is created specifically for the targeted ecology. The OOR experts then work alongside the production team to deliver the mix into the well, and deep into the reservoir, while seeking to protect production and minimize any disruption.

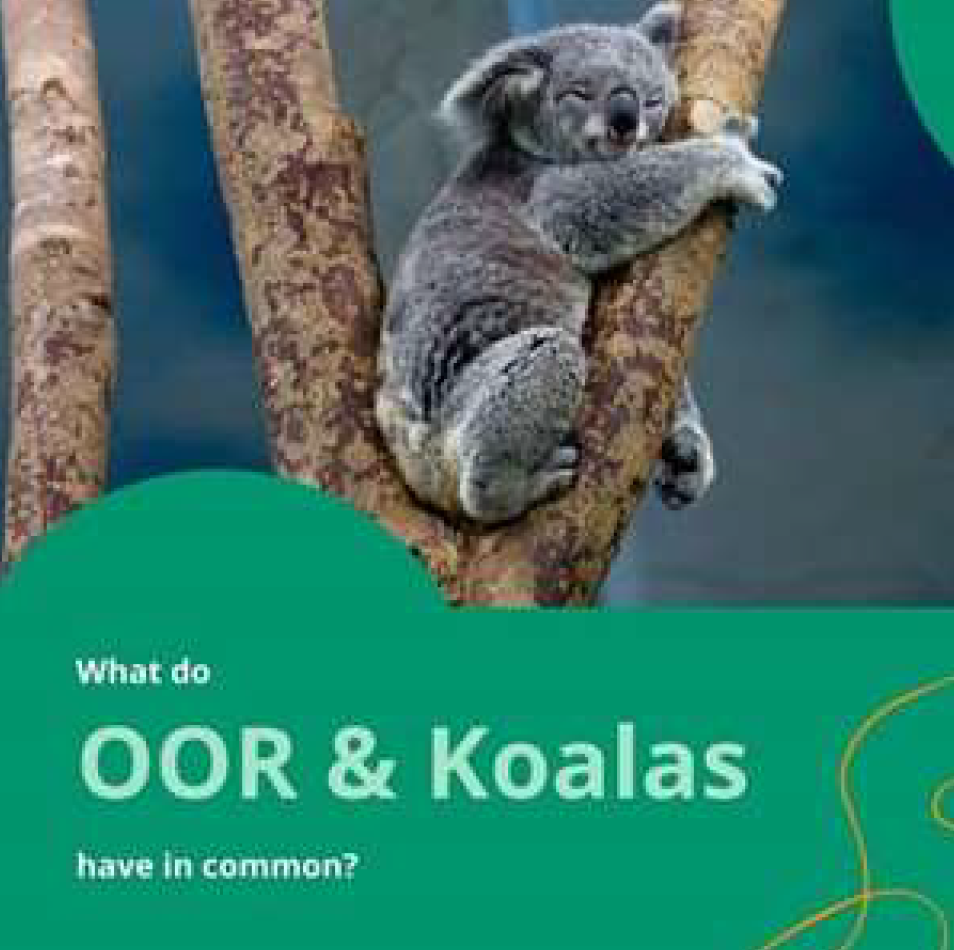

The well is then shut in for a period of time, to enable the nutrients to target the specified microbes (the other microbes leave the nutrients alone), which then multiply and “plume” throughout the reservoir. A single microbe can split in two every 20 minutes. This exponential growth can result in one cell becoming two billion or more within 24 hours.

After a scientifically-calculated timeframe, the nutrient supply is eventually “switched off.” The army of microbes created then subsequently seeks sustenance from elsewhere in the reservoir and targets the water/oil interface, believing it to be much more nutrient-rich there. This becomes hydrophobic as opposed to hydrophilic, breaking the oil down into trillions of smaller droplets and enabling them to be freed to the surface from producing wells and waterflood injection units, Fig. 2.

The results are impressive, with an average production increase of 92%, with even higher results in several cases. The success rate for the treatment, as a whole, is a staggering 94%.

The process should not be confused with traditional microbial enhanced oil recovery (MEOR), which can involve introducing foreign bacteria into the reservoir to target the oil; the OOR process utilizes the microbes that are already resident in the reservoir and, therefore, completely at home in their natural environment.

“Old MEOR” also often utilized sugar-based nutrients that increased production of H2S, with all the expensive cost implications that it brought to companies. The nutrients added to the well under this new OOR process are completely harmless to the surrounding ecology. If you released them outside the well, they would have no impact on the environment at all.

MARKET IMPLICATIONS

Bruce Ferguson, Chief Financial Officer for Hunting, said: “We’re so excited by this technology that is helping increase and prolong oil production across the Middle East, North Sea, Asia, Russia and beyond, with minimal cost implications. It is an absolute game-changer for a sector that is under incredible pressure to continue to produce oil and its subsequent returns while looking to the future for new energy sources.

“It means that producers can concentrate on their existing wells, reservoirs and resources to ensure maximum recovery, saving time, money and wider impact to the environment, as we can focus on retrieving the 65%-plus oil still trapped in existing reservoirs before even thinking about moving on to new ones. This allows us all to enjoy the benefits oil brings to our lives while freeing up capital to explore new ways of powering the planet for future generations.”

The process can go from initial discussion to injector treatment in as little as six months, with a series of gated steps and sampling to enable the team and client to be confident of the way ahead. But, the team is happy to work to the clients’ specified timeframes.

The sweet spot of the process is also very broad, with a reservoir temperature of less than 95oC preferred, but it’s not a deal-breaker. Water pH of between six and eight, and oil gravity from 12o to 42oAPI also help to create the perfect environment, although the process has been proven to work outside these conditions.

PILOT PROJECT

Among the successful operations to date, one test on a North Sea platform undertaken by OOR increased production significantly and helped record the largest measured oil output at the facility in more than five years, Fig. 3.

The pilot, on CNOOC Petroleum Europe Ltd’s Scott platform, approximately 187 km north-east of Aberdeen in the UK, saw the team load the specially-prepared nutrients into a single-well injector to activate microbes resident deep in the reservoir. After being shut in for a number of days, the well was then put back online, with output increasing to the five-years-plus high previously mentioned. More than 25,000 extra barrels of oil were produced during the test period than would normally have been recorded.

The cost of the pilot was paid back in less than a week, and CNOOC and its partners achieved a return on investment of more than 1,000%. CNOOC, which operates Scott with partners MOL Operations UK Ltd, Dana Petroleum E&P Ltd, Edison E&P UK Ltd, and NEO Energy Production UK Ltd, is expected to go to a full injector treatment later this year.

Meanwhile, following a series of sample tests in the Middle East, a national oil company has signed up for a 30-producer treatment program on its extensive network of land-based wells, where it has been operating since the early 1930s. Significant interest is also emanating out of Oman, with a series of injector treatments planned for the country this year. In addition, demand is building in areas as diverse as Eastern Europe, Kazakhstan, Russia and Pakistan, as well as further requests for us of the technology in the aging North Sea basin. The team is currently working on plans for pilot tests with MOL Group, which is active in over 30 countries, for its string of operations in Hungary and Russia.

The OOR team is a lean but globally-focused unit led out of the operation’s headquarters in Aberdeen, Scotland, by the author, an oil services veteran with almost three decades working for several companies, including BP and GE Oil and Gas, as its general manager. He is supported by Grant Fuller, as operations manager, alongside a major network in the wider Hunting family to provide back-up where needed. In the Middle East, Chris Venske is OOR’s engineering and technical sales manager, based in Dubai, while Taj Uddin is operations engineer also operating out of Dubai. Recent recruit Husain AlBaqali is focused on in-country operations, based in Bahrain.

The team has a string of SPE papers and examples of the levels of success that the technology can bring. And the scientists, based in California, are happy to explain to their technical colleagues within operating companies as to the nature of the process and the science behind this glittering success.

Chris Venske noted that there has been a high level of interest from some of the biggest oil producers globally, which have quietly taken a very keen interest in what they know could be very beneficial to them. “We’re loving the fact that we’re involved in some long-term projects while also developing the next stream of potential partners, who are being attracted by the very real results they are hearing and seeing from industry colleagues.

“We truly believe this low-carbon, transitional technology is going to be a boon to the sector. We know oil is going to be with us for decades to come, and if we can get more out of the aging reservoirs, saving time and money for the operators, then we’re happy to help.”

Conversations continue today across the globe with operators, to help them enhance and elongate their production while delaying decommissioning and reducing the risks of dangerous hydrogen sulphide emissions. The future is bright for this truly low-cost, high-return transition technology that requires no new capital expenditure. We all have a lot for which to thank that fussy little Australian marsupial’s digestive system.

THE AUTHORS

Roger Findlay , General Manager for Organic Oil Recovery within Hunting Energy Services, has over 25 years of oil & gas experience, working for both operators and service providers in a number of disciplines, including Mechanical Engineering, Project Management and Process Optimization. He holds an MSc degree in Project Management from Aberdeen University and a BSc degree in Industrial Design from Napier University in Edinburgh, Scotland. He is a member of the Society of Petroleum Engineers (SPE) and the European Association of Geoscientists and Engineers (EAGE). roger.findlay@organicoilrecovery.com