Oil Field Service

A New Direction in Enhanced Oil Recovery: Micro Oil Droplets

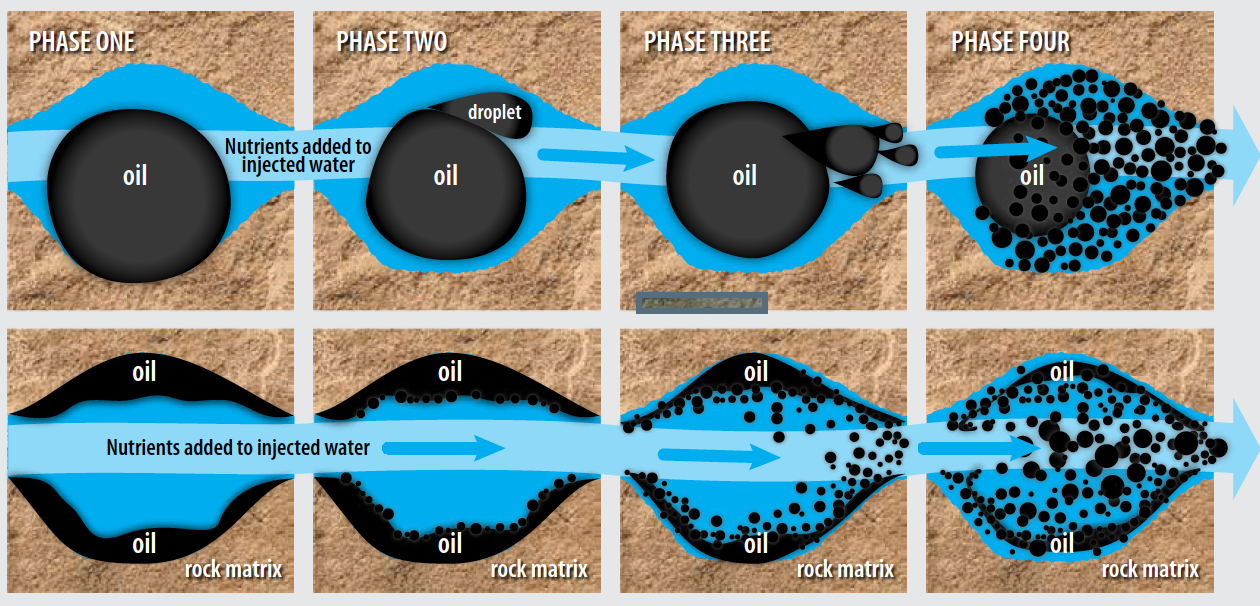

The Titan Process® injects nutrients into a reservoir and induces certain targeted microbes to become oleophilic [oil loving] and attach themselves to oil droplets. The microbes then physically dislodge and uniquely break down the trapped oil within the pore spaces into smaller droplets which can be recovered more efficiently. This oleophilic activity is an entirely new direction in the field of enhanced oil recovery. This process is simple, efficient, inexpensive and 100% environmentally friendly.

The Titan Process uses indigenous microbes that have already adapted to their environment over millions of years. The Titan Process does not inject microbes into oil fields and only uses resident microbes. Problems and complex solutions to aid in the survival of injected microbes to deal with reservoir pressure, saline content and temperature are therefore not encountered.

With the Titan Process microbes are able to multiply by tens of thousands to millions of times on specialized nutrients, and their small size helps them penetrate deep into the formation where they act to break up and mobilize previously trapped oil droplets, which have been left behind by both Secondary and Tertiary recovery methods.

Improving Ultimate Reservoir Performance

The Titan Process stimulates naturally occurring microbes within the oil reservoir. They dislodge and then uniquely break up oil globules within the pore spaces in the rock matrix, which then become recoverable. Microbes can also create a temporary unique natural mild emulsion within high permeability thief zones. This temporary emulsion blocks thief zones and allows for a more efficient waterflood sweep. The Titan Process also creates a well bore clean-up phase.

The process is all natural, no harsh chemicals are used and there are no adverse effects in the reservoir. A single well test can be easily implemented to gain important performance predictability for an entire field.

Review the five Society of Petroleum Engineers (SPE) papers written by Titan’s customers acknowledging the success of the Titan Process on their oil fields.

Organic Oil Recovery Overview

Five-Step Process

A start to finish pilot test takes only 120-180 days. After this a field-wide program can be planned and implemented.

Organic Oil Recovery Overview

Five-Step Process

A start to finish pilot test takes only 120-180 days. After this a field-wide program can be planned and implemented.

The application of the OOR Process® generally consists of five-steps:

Step 1 - Initial Field Screening

This is where we analyze the oil field reservoir for various technical aspects. Our engineers review basic reservoir information provided by the customer to make sure the reservoir would be a good candidate for Organic Oil Recovery.

Step II - Production Water Sampling

Production water samples from the field are collected and sent for laboratory analysis. A water collection kit is sent to the oil field to collect water samples from 2-4 production wells to be analyzed in our lab. The lab analysis of the well water samples when complete and documented are sent to the customer in a 10–15-page Laboratory Report. If the lab work was successful, then a recommendation is made to proceed with some pilot wells on the field.

Step III - Field Application to 2-4 Production Wells

This is an In‐situ Microbial Response Test. This step is to verify the nutrient formula developed in the lab can be applied successfully in the field. In advance of the first 2-4 pilot well applications Titan’s technical team will meet by Zoom with the customer engineers and field personnel to review and go over the steps necessary and the equipment that will be needed for the well tests to be conducted. This usually takes place with 1‐3 meetings, so all aspects are well understood and coordinated between the field personnel and the delivery team from Titan.

Step IV - Pilot Injection Well Application

If the results from the production well tests are positive, then an injector well pilot would be in order. This will allow for a much larger area of the reservoir to be treated with the Organic Oil Recovery process.

Step V - Full Field Roll-Out

With a successful injector pilot then a roll-out schedule of the field can be planned and implemented.