Changing the Recovery

Factor in Global Oil Reservoirs

Changing the Recovery

Factor in Global Oil Reservoirs

HUNTING PLC ANNOUNCES ACQUISITION OF ORGANIC OIL RECOVERY TECHNOLOGY ASSETS

Hunting PLC has acquired the assets related to Organic Oil Recovery (OOR) technology from Titan Oil Recovery, marking a strategic expansion of its global capabilities. This asset acquisition unlocks greater value for customers by combining OOR’s proven performance with Hunting’s extensive infrastructure, deep technical expertise, and international reach. With over 150 years of industry leadership, Hunting is well-positioned to scale the OOR technology across key regions—delivering enhanced support, broader access, and a stronger platform for driving operational success.Contact Information

Eastern Hemisphere Inquiries:guido.dantonia@hunting-intl.com

zach.broussard@hunting-intl.com

To learn more about the acquisition, we invite you to read our official announcement: Hunting PLC Press Release.

We look forward to supporting your operations with the added strength of Hunting PLC’s global reach and technical leadership.

Titan Oil Recovery Inc. shareholders, please visit Koala Royalties for the latest royalty details.

Summary

OOR is a leap forward in enhanced oil recovery

Titan's Organic Oil Recovery is an ecological advancement in enhanced oil recovery (EOR) technology. It is biodegradable, low cost, requires no capital expense and has a much lower carbon footprint than all other EOR methods. It is a proven science which uses nature itself to increase oil production onshore and offshore.

When used with waterfloods, the success rate is 98% from over 244 injector well applications. It has been applied to 75 oil fields on five continents.

Case Study: Offshore Platform CA.

Expected Production - 105,000 bbls Actual Production - 187,000 bbls

RESULTS

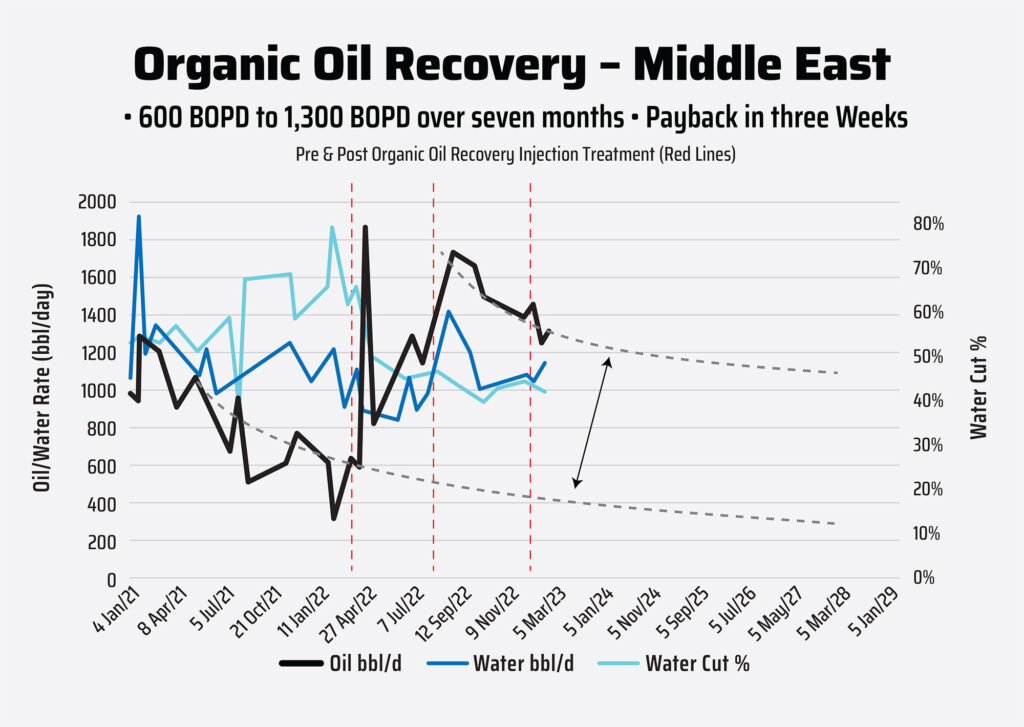

Latest Results from the Middle East

In the adjoining Graph you can see full field results of a significant oil increase.

HUNTING

Hunting Energy Services — Our Partner in 29 Countries

Hunting has embraced Organic Oil Recovery as next-gen technology and they are actively marketing to their customers. Hunting is the world’s oldest oil service company, established over 140 years ago. The company provides products and services to the upstream oil and gas industry. Sales and service operations are located in the major oil centres of the world, comprising over eighty company owned facilities and a network of more than sixty licensed partners.

SERVICE

A New Direction in Enhanced Oil Recovery

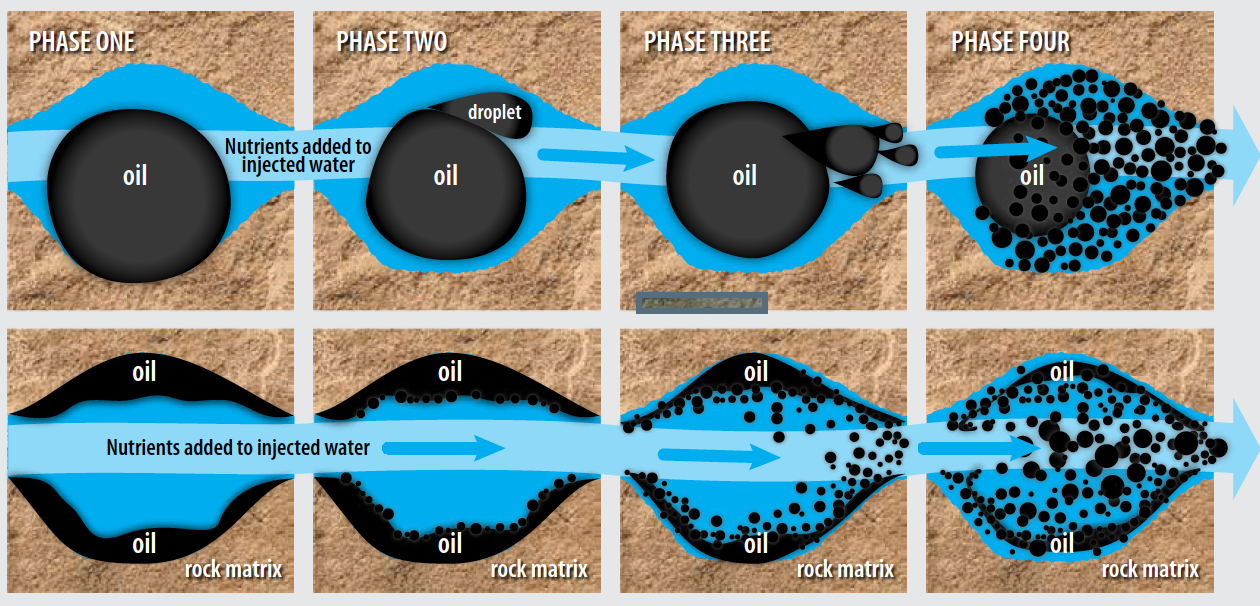

The Titan Process® injects nutrients into a reservoir and induces certain targeted microbes to become oleophilic [oil loving] and attach themselves to oil droplets. The microbes then physically dislodge and uniquely break down the trapped oil within the pore spaces into smaller droplets which can be recovered more efficiently. This oleophilic activity is an entirely new direction in the field of enhanced oil recovery. This process is simple, efficient, inexpensive and 100% environmentally friendly.

Global Affiliates in 35 Countries